When it comes to managing a fleet there are two strategies that come to mind, corrective maintenance and preventive maintenance. Approaching your fleet with the right maintenance strategy is essential. Not only will it ensure that your vehicles are safe to operate, but it will help raise your fleet’s productivity and bring value to your business. Let’s examine these two fleet maintenance strategies in detail.

Corrective Maintenance:

Simply put, corrective maintenance involves correcting issues after they’ve come to light. Let’s say a piece of equipment in your truck becomes faulty. So, you take your truck to the mechanic to get it fixed. Also known as reactive maintenance, this approach means waiting for something to go wrong, before reacting with corrective measures.

Preventive Maintenance:

Preventive maintenance involves being proactive about the mechanical soundness of your vehicles. It means getting ahead of minor problems before they become major issues. By eliminating the potential for small issues to snowball into bigger ones, the operational condition of your fleet stays in check.

Which Option Should I Choose for My Fleet?

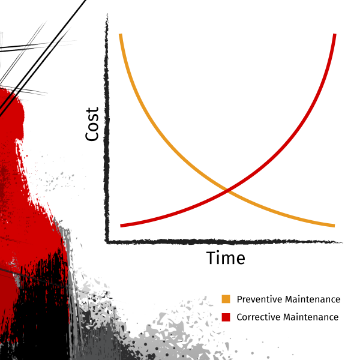

Initially, the preventive approach seems to spike costs, while the corrective strategy reduces spending. This makes sense because getting on a preventive maintenance program will have you paying a small fee up-front. With corrective measures, no payment is made until necessary (meaning until a breakdown occurs). When this happens, however, the corrective approach quickly results in bills and costs far outweighing that of the preventive program. With a preventive strategy, smaller issues get fixed as they come up, incurring only minor costs. If they are left to become larger problems, their repair costs (not to mention equipment replacement) will quickly add up. Over time, a corrective maintenance strategy will always result in higher spending. In fact, the longer a fleet operates with a corrective strategy, the higher its repair costs grow. If you’re planning on running your fleet long-term, consider saving money with a preventative maintenance program.

Now, let’s examine corrective and preventative maintenance from some other perspectives:

Driver Safety:

When considering the performance of your fleet, the safety of your drivers should be a top priority. When drivers wait for a roadside breakdown before getting their trucks serviced, every minute spent on the road is putting them at risk. Not getting smaller issues checked out increases the risk of sudden breakdowns, unexpected failures, and accidents. On the other hand, a preventative maintenance program prevents all of these possibilities by constantly ensuring the mechanical soundness of your vehicles. Drivers can rest assured that their trucks are operationally sound, and free of any faults that could be putting them at risk on the road.

Emergency Repairs:

Because preventative maintenance involves getting ahead of issues, it reduces the need for emergency truck repairs down the line. When smaller issues get swept under the rug, they essentially become an emergency repair waiting to happen. By following a corrective maintenance strategy, fleet managers are simply waiting for problem upon problem to arise, without thinking to prevent them in the first place. We suggest not waiting for a faulty piece of equipment to lead to a roadside breakdown and emergency repair situation. By following a preventive maintenance program, fleet managers can get ahead of the curve, and keep up the long-term integrity of their vehicles.

Budgeting & Repair Costs:

Let’s face it, no one wants to be spending money on truck repairs. Budgeting is an incredibly important part of fleet management, regardless of the size of your fleet. Engine overhauls and replacing entire systems can seriously affect your budget plans. Spending a small, consistent amount on a preventive maintenance program will prove to be much more budget-friendly than paying for expensive repairs. Getting ahead of a problem, especially one as debilitating as a broken-down vehicle, will always be more budget-friendly.

Eliminating Vehicle Downtime by Preventive Maintenance:

Let’s say you run a fleet of 10 trucks. Would it make sense to constantly work with just 7 or 8? By regularly having to send trucks off to get serviced, you’re downplaying the operational capacity of your fleet. Waiting longer periods between services while your trucks are in prime condition may seem tempting. But as soon as a mechanical fault does arise, the time and money you think you’ve saved quickly add up. Vehicle downtimes reduce the capacity of your fleet, and repair work and replacements can get very pricey. Preventive maintenance practices involve regular, quick check-ups of your vehicles. If smaller problems come up, they’ll be much easier, and cheaper to deal with. Taking your vehicle off the road for a 20-minute run-down will always beat having them sit at the truck shop for days.

Fuel Mileage:

With rising gas prices and long hours on the road, the simple operating cost of fueling your vehicles can get expensive fast. What fleet manager wouldn’t want to maximize their vehicle’s fuel mileage? One approach is ensuring that the various components of your vehicle are working well. Getting moveable pivots and joints greased regularly will prevent them from wearing out. A maintenance checkup can bring other fuel-costing issues to light, like poorly inflated tires, clogged fuel filters, or badly adjusted brakes. Following a proactive maintenance approach will not only save you from further complications but also fuel costs on the road.

Final Thoughts on Preventive Maintenance:

Knowing that your vehicles are the lifeline of your business, taking proper care of them is essential. A preventive maintenance strategy benefits not only your vehicles but your drivers, and your entire business. By spending a small, fixed amount on a preventive maintenance program that fits your needs, you’ll be saving money continually down the line. Not only that, but your vehicles will be operationally sound for many more years to come, bringing you great returns on investment.

If you’d like to get started on a preventive strategy, our maintenance managers are ready to help. Reach out to us for a consultation, and we’ll set your fleet up on a preventive maintenance program that suits your needs.